Hygienic Sanitary Check Valves are also commonly referred as “Non-Return Valve”.

The Check Valve also referred as Non Return Valve opens when the pressure below the valve plug exceeds the pressure above the valve plug with spring force or dead weight.

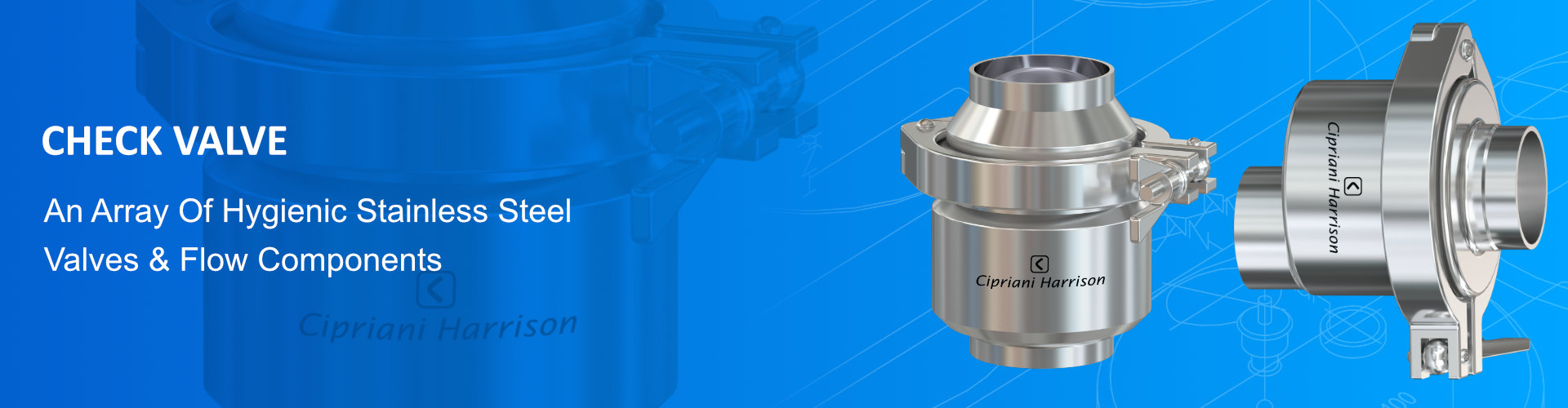

Cipriani Harrison 64-Series Check Valve are used in process piping system where the fluid is to be passed through one direction and the reverse flow is to be avoided.

Cipriani Harrison Check valves are designed keeping in mind the stringent hygienic design criteria and available with different version to suite its respective application.

Cipriani Harrison 65-Series Check valve are designed ensuring the stringent requirement of hygienic sanitary guidelines.

The 65-Series Check valve is made from High quality forged or bar stock raw material.

This valve works on a dead weigh Principle and do not use any springs, which enables it to be used on low Pressure application.

The 64-Series Check Valve are made of High quality forging .

The self-draining design of the lower valve Body enables no residual accumulation and Flushing of the product. Special engineer construction of the disc Ensures to resist heavy pressure hammer, Minimizes the resistance of the flow and Guides the valve plug for better repeatability.

The 65-Series check valve are designed for Low pressure application, where the product Pipe line has low pressure still demands a unidirectional flow.

The 65-Seies valve is designed for horizontal installation. The valve body is designed & precisely machined to ensure no residual accumulation and the product if flushed through the pipeline.

Cipriani Harrison Check valves are available with a wide array of end connection like Weld End, Sanitary Clamp End, Union or Threaded End, I-Line and Flanged end connection.

The valves are available in different international standards like ISO, DIN, RJT, IDF, etc to meet different regional needs.